Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are critical components used to create watertight and secure connections between concrete pipes in various applications, including drainage systems, sewer systems, culverts, and stormwater management. These seals are designed to prevent leaks, maintain the structural integrity of the pipe system, and ensure the effective flow of fluids. Here’s a detailed description of concrete pipe seals:

1. Purpose and Function:

- Watertight Sealing: Concrete pipe seals are primarily used to create a watertight seal at the joints of concrete pipes. This prevents water infiltration and exfiltration, ensuring that wastewater or stormwater flows within the pipe system are properly contained.

- Structural Integrity: In addition to preventing leaks, these seals also help maintain the structural integrity of the pipeline by preventing soil erosion around the pipes and preserving the bedding and backfill materials.

- Alignment: Concrete pipe seals aid in aligning and connecting concrete pipes, ensuring a secure and uniform fit.

2. Types of Concrete Pipe Seals:

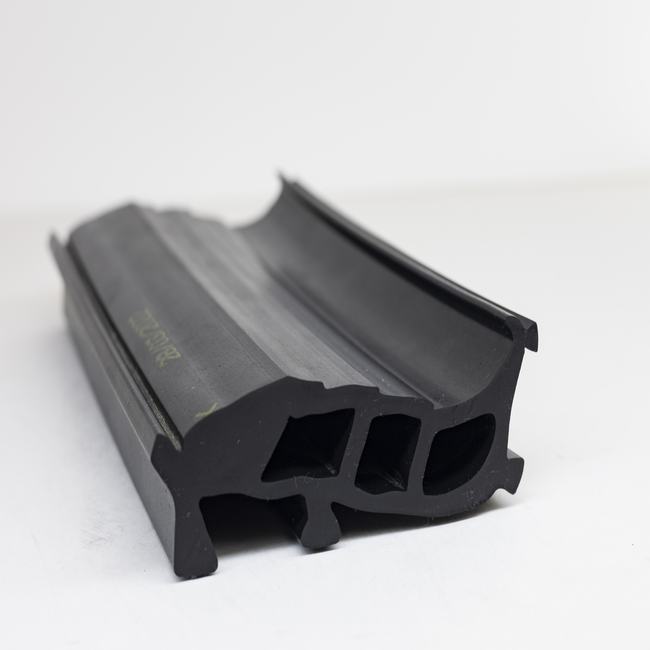

- Rubber Gaskets: These are among the most common types of concrete pipe seals. They are typically made of resilient rubber materials, such as EPDM (ethylene propylene diene monomer), neoprene, or natural rubber. Rubber gaskets create a tight and flexible seal when compressed between concrete pipe joints.

- O-Ring Seals: O-ring seals are circular elastomeric gaskets designed to fit into grooves or recesses in the pipe’s spigot and bell ends. When the pipes are joined, the O-ring compresses to form a reliable seal.

- Compression Seals: Compression seals are composed of rubber or synthetic materials and are designed to withstand significant compression. They are often used in applications where joint movement or deflection is expected.

- Lubricated Seals: Some concrete pipe seals are pre-lubricated with a compatible lubricant to facilitate assembly and ensure proper sealing during installation.

3. Materials:

- Concrete pipe seals are typically made from resilient and durable elastomeric materials that can withstand the harsh conditions of buried pipelines, including exposure to chemicals, moisture, and temperature fluctuations.

4. Installation:

- Proper installation is crucial to ensure the effectiveness of concrete pipe seals. This includes correctly positioning the seals within the pipe joint, applying the appropriate lubricant (if required), and ensuring that the pipes are properly aligned and fitted.

5. Maintenance:

- Concrete pipe seals are generally low-maintenance components. However, periodic inspections may be necessary to check for signs of damage, wear, or deterioration, especially in heavily trafficked or corrosive environments.

6. Compliance with Standards:

- Concrete pipe seals are subject to industry and regulatory standards to ensure their quality and performance in various applications. These standards may include ASTM (American Society for Testing and Materials) specifications and local building codes.

7. Applications:

- Concrete pipe seals are widely used in the construction and maintenance of stormwater drainage systems, sanitary sewer systems, culverts, irrigation pipelines, and other infrastructure projects.

In summary, concrete pipe seals are essential components in the construction and maintenance of concrete pipe systems. They provide watertight seals, preserve structural integrity, and ensure the efficient flow of fluids within these systems. Proper selection, installation, and maintenance of concrete pipe seals are critical to the long-term performance and durability of concrete pipelines.